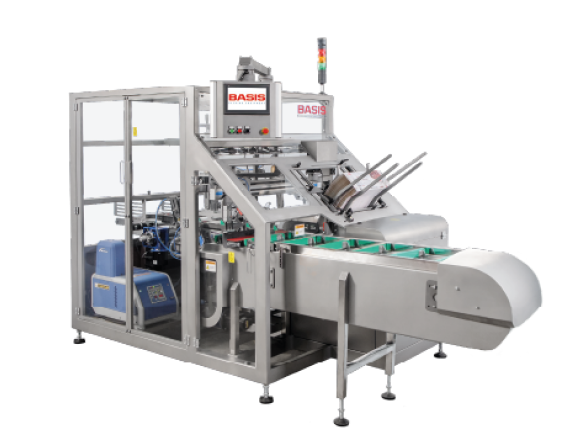

BASIS 50ECO CARTONER

The Intermittent Cartoning Machine is specifically engineered for precision packaging of products into cartons through a step-by-step, controlled process. Ideal for small to medium production runs, it provides unmatched flexibility and accuracy, especially in industries where frequent changeovers and format variations are required.

Key Features:

- Step-by-step cartoning mechanism for controlled and reliable operation.

- Compatible with varied carton shapes and sizes, including tuck-in and glue-sealed formats.

- Ideal for applications with frequent SKU changes and lower volume production.

- Highly modular and compact design fits easily into existing production lines.

- User-friendly interface for quick format adjustments and minimal downtime.

Benefits:

- Perfect for pharmaceuticals, cosmetics, food, and personal care products.

- Reduces product waste with high-precision alignment and filling.

- Offers versatile packaging solutions for custom or irregular carton sizes.

- Easy integration with manual or automatic product feeding systems.

- Cost-effective solution for businesses needing high packaging flexibility without high-speed demand.

Whether you’re producing multiple product types or need dependable performance at moderate volumes, this flexible cartoning system delivers both precision and adaptability—making it a smart investment for diverse manufacturing environments.

Get OfferTechnical Specifications

| Type of loading element | Feeding conveyor |

|---|---|

| Type of glue | Hot melt glue |

| Capacity | 60 / m |

| Box dimensions : | length 30 – 220 mm / width 20 – 120 mm / depth 125 - 400 mm |

| Dimensions | 3005х1445х2173 mm |

| Power | 5 Kw |